1070799

License Number

Call Us

La Puente, CA 91746

Visit Us Here

24 Hour Service

7 Days a Week

We Offer The

Slide title

Fastest

Button

Slide title

Cleanest

Button

Slide title

Budget Friendly

Button

Slide title

Most Organized

Button

On-Site Plumbing Service

Showtime Plumbing provides top-tier plumbing services, ensuring your home’s plumbing system remains pristine. Don’t let plumbing woes slow you down; call the pros today!

Welcome to

Showtime Plumbing

Are you tired of dealing with leaky faucets, clogged drains, or plumbing emergencies? Look no further! Our professional plumbing services are here to rescue you from all your plumbing woes. With years of experience and a dedicated team of skilled plumbers, we guarantee top-notch service and customer satisfaction.

Satisfaction Guaranteed

At Showtime Plumbing LLC, we stand behind the quality of our work, guaranteeing 100% customer satisfaction for all your plumbing needs.

Expert Services

Our highly trained and seasoned professional team delivers superior plumbing solutions, fulfilling your needs with precision and efficiency.

Licensed & Insured

As a fully licensed and insured business, we bring you peace of mind, ensuring every project is done with utmost safety and compliance with regulation standards.

Introducing Us

Reliable Plumbing Services At Your Doorstep!

Showtime Plumbing LLC is a dedicated plumbing service provider offering comprehensive solutions for your residential and commercial needs. Based in La Puente, CA, we take pride in serving our local community with superior services, drawing from our extensive experience and high standards of professionalism.

- Certified Specialists

- Quality Service

- Satisfaction Guaranteed

- Expert Services

- Licensed & Insured

- Prompt Response

- cras tincidunt

- lobortis feugiat

Plumber & Repair Services

For All Your Plumbing Needs, We Have You Covered!

Our skilled plumbers at Showtime Plumbing LLC strive to provide top-notch repair services, ensuring your plumbing system performs at its best. No matter the complexity of your plumbing needs, we have the expertise and resources to service them effectively. We’re committed to delivering expert solutions with quick turnaround times, ensuring your space remains functional and safe.

What We Offer

Exceeding Your Expectations

At Showtime Plumbing LLC, we offer a comprehensive range of specialized plumbing services tailored to residential and commercial needs. Our experts handle everything from drain and sewer management to water heater services and garbage disposal. Coupled with state-of-the-art tools, our team ensures each task is executed precisely, per safety standards, and without disrupting your daily routines.

Sewer Hydro-Jetting Services

Our hydro-jetting services effectively remove stubborn blockages and ensure your sewer lines are free of obstructions.

Sewer Cast Iron Descaling

Counteract years of build-up in old pipes with our cast iron descaling service, restoring your sewer system’s efficiency without requiring invasive procedures.

Sewer Pipe Bursting

Our sewer pipe bursting services offer a trenchless solution to replace damaged pipes, minimizing the impact on your property and the surrounding area.

Drain Cleaning Services

With our meticulous drain cleaning services, we prevent backups and extend the longevity of your systems, assuring your drains stay free-flowing.

Sewer Lining Services

Our no-dig sewer lining technology creates a seamless and robust inner lining within your existing pipes, reducing the risk of leaks and breaks.

Sewer Camera Video Inspections

Utilize our video inspection services to quickly and accurately identify issues within your sewer lines, ensuring precise repairs and maintenance.

Why Choose Us

Fixing Plumbing Problems One Call at a Time

With a single call, our team is on the frontline, ready to resolve your plumbing woes with swift precision and unmatched expertise. We understand the value of immediate, effective, long-lasting plumbing solutions tailored to your needs. Our promise is a hassle-free service experience that turns your call into a solution, leaving you with the peace of mind that your space is in the best hands.

Affordable Price

LoExperience superior plumbing service at competitive pricing, ensuring you don't have to compromise on quality for cost-effectiveness.

Expert Plumber

Our expert plumbers are the cornerstone of our service, bringing a wealth of experience and skill to solve even the most complex plumbing challenges.

Quality Improve

Commitment to quality enhancement is at the heart of our work, bringing you advanced plumbing solutions that set a new standard for excellence..

100% Certified

Rest assured, our plumbers are 100% certified, upholding industry standards to provide services that are as reliable as they are compliant.

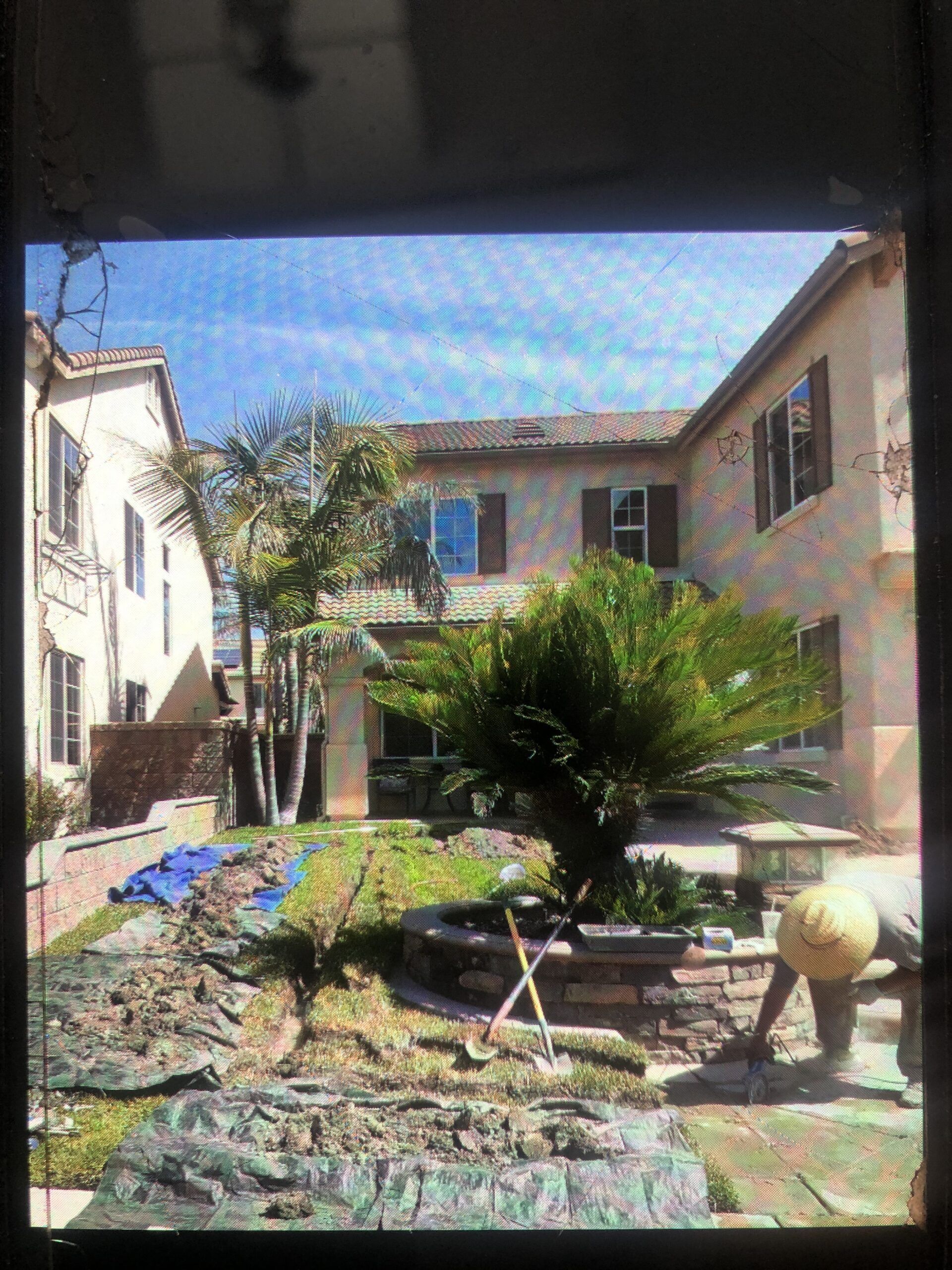

Our Previous Works

We Are Committed to Delivering Effective and Reliable Solutions

Witness our unwavering commitment to excellence as showcased in our gallery of previous works. Each case illustrates our dedication to delivering robust and effective plumbing solutions tailored to the unique needs of our diverse clientele. From simple repairs to complex installations, our expert craftsmanship, innovative techniques, and attention to detail remain consistent, ensuring reliable functionality that stands the test of time.

Emergency Plumbing Service 24/7 Availability

Our Emergency Plumbing Service offers around-the-clock assistance, ensuring help is always available during a crisis. Swift and dependable, we’re here to seamlessly tackle urgent plumbing needs any time, day or night.

Contact Us

Fill Out the Form and Enlist Our Services.

Ready to address your plumbing concerns? Fill out our contact form to enlist professional, efficient service you can trust to resolve any issue with precision and care.

Contact Form

We will get back to you as soon as possible.

Please try again later.

Testimonials

Feedback From Our Clients

Discover the experiences of those who’ve entrusted us with their plumbing needs in our Testimonials section. Honest feedback from our clients provides insight into the quality of artistry and customer service we consistently deliver. Each testimonial is a testament to our commitment to exceeding expectations and establishing lasting relationships with our clients.

⭐⭐⭐⭐⭐

he’s really good at his work he’s clean meaning he picks up after himself when it’s done he did my sink. It came out good and he put water heaters in to I recommend them to anybody.

Juliet O.

2023-05-30

⭐⭐⭐⭐⭐

Had a leak in our sink and Vince showed up same day and fixed it! Thank you so much!

Lily G.

2023-05-22

⭐⭐⭐⭐⭐

Vincent was very responsible and got the job done in a short amount of time.

Anahi G.

2023-05-22

⭐⭐⭐⭐⭐

Hired Vince already for several demanding projects and love working with him. Good, reliable and responsive old-fashioned plumber, looking for the way to make my life and the problem he is called for - easier and not more complicated as many services do. Thumbs up!

Igor B.

2023-05-22

⭐⭐⭐⭐⭐

Awesome service! Great work! very affordable. Showtime had provided me the most excellent services and help with my plumbing problem.

Mike N.

2023-05-22

⭐⭐⭐⭐⭐

After the caca Monster plugged my main pipe, this guy came to the rescue and saved the day! Best pumping service this side of Texas! And his truck is awesome! Just wish it had San Francisco Giants players and logos instead of Dodger ones.

Eric “El Cucuy” S.

⭐⭐⭐⭐⭐

Hello,Mr. Vincent (the plumber) was very knowledgeable, well versed, surpassed punctuality (arrived on-site early). He took care of the issue and furthermore provided a receipt.Kind Regards,

Bertha C. Torres

This email was approved by Bertha C. Torres.*

Annette T.

⭐⭐⭐⭐⭐

Vince is a very knowledgeable plumber. I called 3 other plumbers and they could not unclog the tub. They quoted me 6500 for replumbing the tub. Vince came nd unclothed the tub and saved me alot of money. I recommend Vince for all your plumbing needs.

Bernie R.

⭐⭐⭐⭐⭐

Best price in town and shows up on the weekend.

AK

⭐⭐⭐⭐⭐

I could always count on Vince to do a great professional job when I'm in need of his services. He's prices are fair but his work speaks for itself, he's reliable, friendly, and fast. Hit him up if you need the job done right and quick, you won't regret it.

Ernie G

⭐⭐⭐⭐⭐

Both my toilets were stopped up today. I called showtime plumbing he came out. Did a great job? I would use him again 5 star. Prices are great I would recommend. Ham, whoever needs a plumber.

Leonard R.

⭐⭐⭐⭐⭐

We have used Showtime Plumbing, LLC for over twenty years for all of our plumbing needs. The owner of the company, Vince, can always be counted on for any of our plumbing issues. He replaced the plumbing lines for our whole house with PEX. We have never had a problem with , ihe installation. From installing toilets, kitchen faucets, hot water heaters and clearing drains he can be counted on for professional and economical service. As a matter of fact we now consider him family. We will have no other plumber resolve our plumbing problems. Ben and Barbara, satisfied customers.

Barbara Santa M.

⭐⭐⭐⭐⭐

We had an emergency plumbing issue so we contacted Showtime Plumbing and they were able to fix it quick! Great service and quality, I would definitely recommend them for your plumbing needs!

Priscilla G.

⭐⭐⭐⭐⭐

Great job on hot water heater replacement.

Showed up on time, quality replacement water heater.

Provided clear invoice and easy electronic payment!

John C.

⭐⭐⭐⭐⭐

Did numerous projects for me from main drain and replaced underground gas line

Daniel V.

⭐⭐⭐⭐⭐

I was in a pinch this past Sunday 3/3/2024. My main galvanized water main / PVC crimp - coupler / meter / broke right off. I reached out to Vince, interrupting his Sunday Dodge game, and he came over to help me get water to the house for Monday’s repairs. He gave me an awesome quote. He was help full. Arrived with his team member early Monday morning. Replaced from water meter to the front of the house with copper “L”. Dug the trench and put the grass back. Pretty awesome job. Got the job done pretty fast. I would highly recommend.

Ken AEM

Quick Links

Our Services